It’s been great to see so many people discover the joy of spinning yarn on a drop spindle. A lot of questions come up along the way, including ones on how to deal with problems that come up. Here are some issues that new spinners run into as they work with the top-whorl drop spindle, and my recommendations on how to fix them.

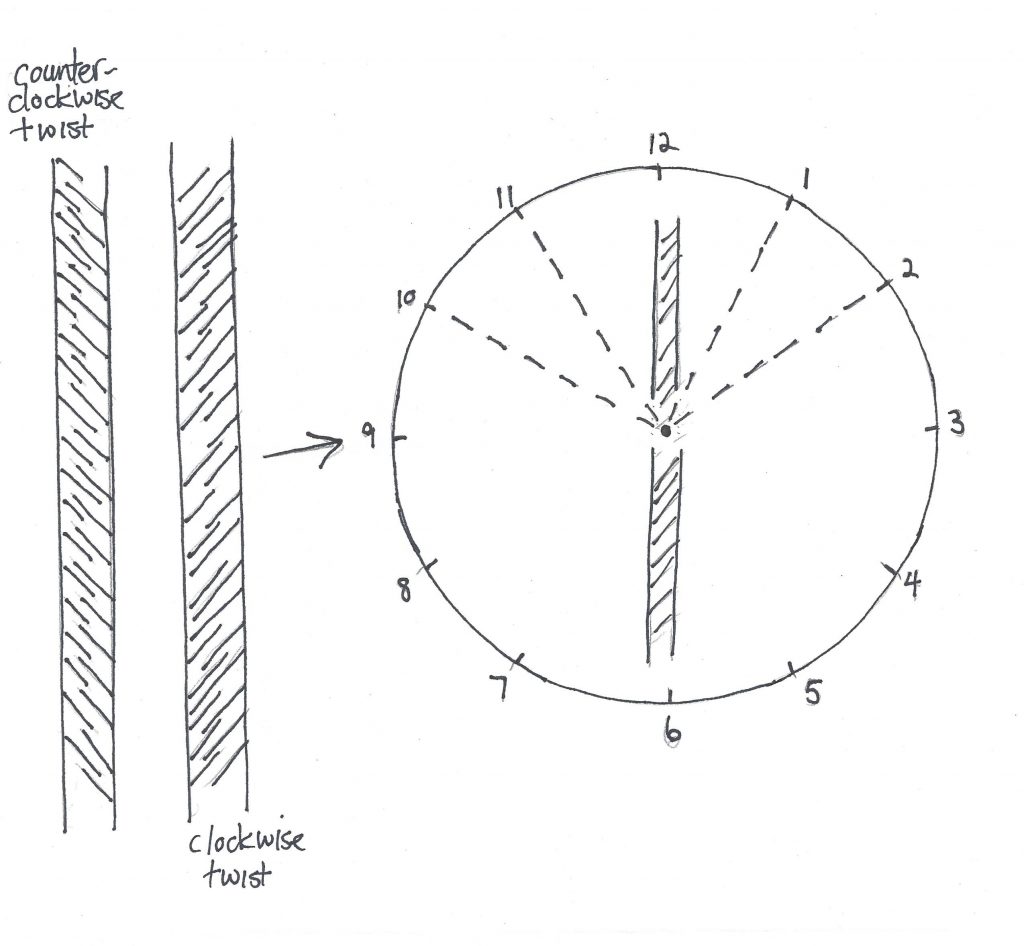

–Fibers drift apart or won’t hold together after I spin them: This usually means that there isn’t enough twist to hold your fibers together. As you feed the fiber into the twist, be sure that your fingers aren’t stopping or interrupting the spin motion; sometimes, as you’re pulling your fingers away, you actually pluck the string, and that will slow down your spindle. Look at your spun single: if you compared the angle of the twist to a clock, try making the angle of twist point to somewhere between 1 and 2 (or between 10 and 11 if you spin counterclockwise).

Also, the amount of twist you need varies on the fiber you’re working with. Merino generally needs less twist than alpaca to hold together well, and short fibers need more twist, and sooner, than longer fibers do. And, make sure that you are not removing twist as you wind the single onto the shaft of your spindle. An overhand motion will add—or take away—twist, so check your technique there. And, thin singles need more twist than thick singles do.

–Fibers drift apart or won’t hold together AS I spin them: This means that the twist isn’t getting into the fibers before the weight of the spindle pulls the fibers apart. The fibers should be fully supported by your fiber hand until they have passed through the drafting zone and entered the twist. Also, don’t pre-draft long lengths of thin slivers of fiber; in fact; it’s better to just loosen the fibers a bit rather than pre-draft them.

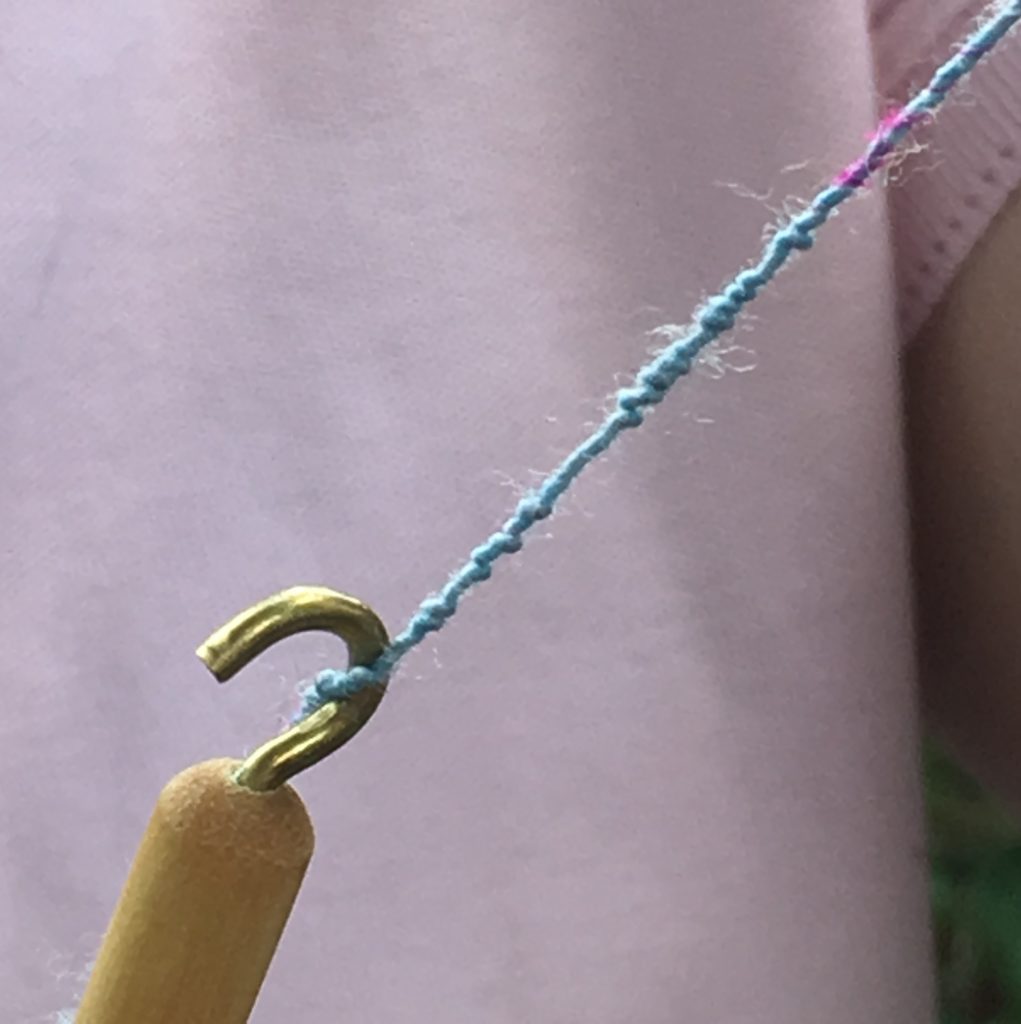

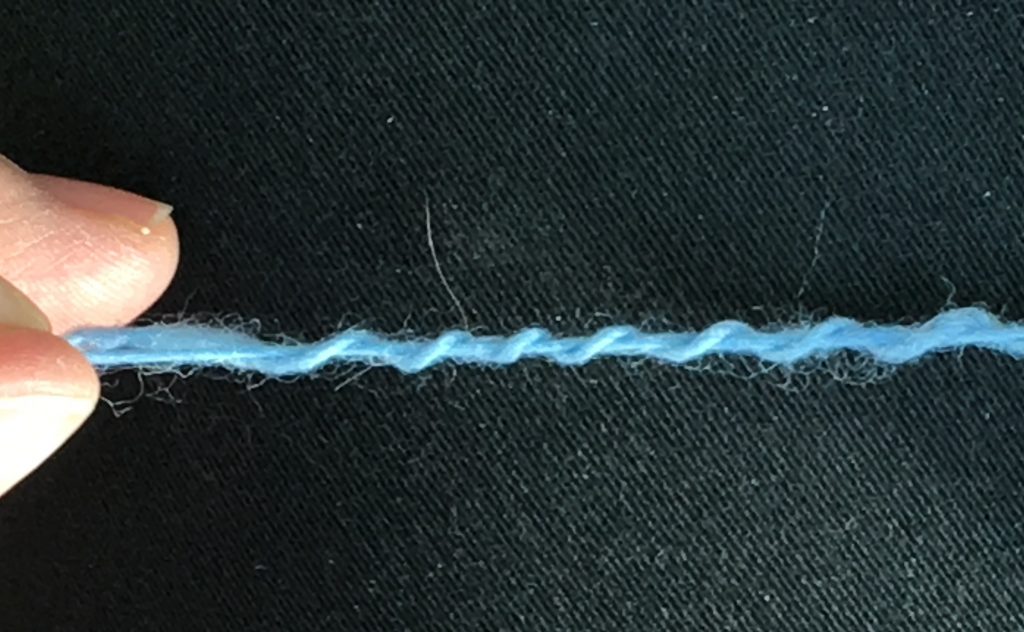

–Single kinks up in places: This is a sign of a couple of issues—too much twist, and thick and thin spots in your single. Twist moves to the thin spots, and away from the thick spots, so the thick spots will look underspun, and the thin spots will twist back on themselves. Spinning an even single just takes practice, and keeping your fiber supply loose but controlled will help.

Overspun yarn will look overspun along the entire length of the single. You’ll get little pigtails and some hard spots, and your single may even break at the thin spots. If it’s just been overspun along a few yards, you can secure your spindle and unroll the single out for a few yards, then draft out some unspun fiber from your fiber supply; this will give the extra twist some place to go. Or, you can just let your spindle go and let it unspin until the pigtails go away. If you have overspun quite a lot of your single, you can secure that spindle and use another spindle spun SLOWLY in the opposite direction to take out some of the extra twist.

–I want to make my single finer/thicker: This is all about how much fiber is released into the twist at a time. Less fiber = finer single; more fiber = thicker single. It can be a little tricky to see how much fiber you actually need, and it’s probably less than you think. To see how much you really need, deconstruct a yarn that you want to mimic that is made of fiber similar to what you’re spinning: pull apart the singles, then untwist a single and look very closely at how many fibers are twisted together in it. Then, take a little bit of fiber and practice drafting out a similar amount. Remember that the amount of twist needed will change as the diameter of your single changes: thick singles need less twist, and finer singles need more twist.

–I have thick and thin spots in my single: This is usually caused by uneven drafting. The advice is normally to loosen your fibers before you spin so that they’ll pull smoothly through your hands and into the twist. However, pre-drafting your fiber has to be done carefully: if you pull too hard, you can create thick and thin spots in your fiber supply, which then create thick and thin spots in your single. If you pre-draft, pull until you feel the first ‘give.’ Alternatively, you can loosen the fibers in a braid, for example, by gently spreading the fibers out across the width of the braid, rather than along its length.

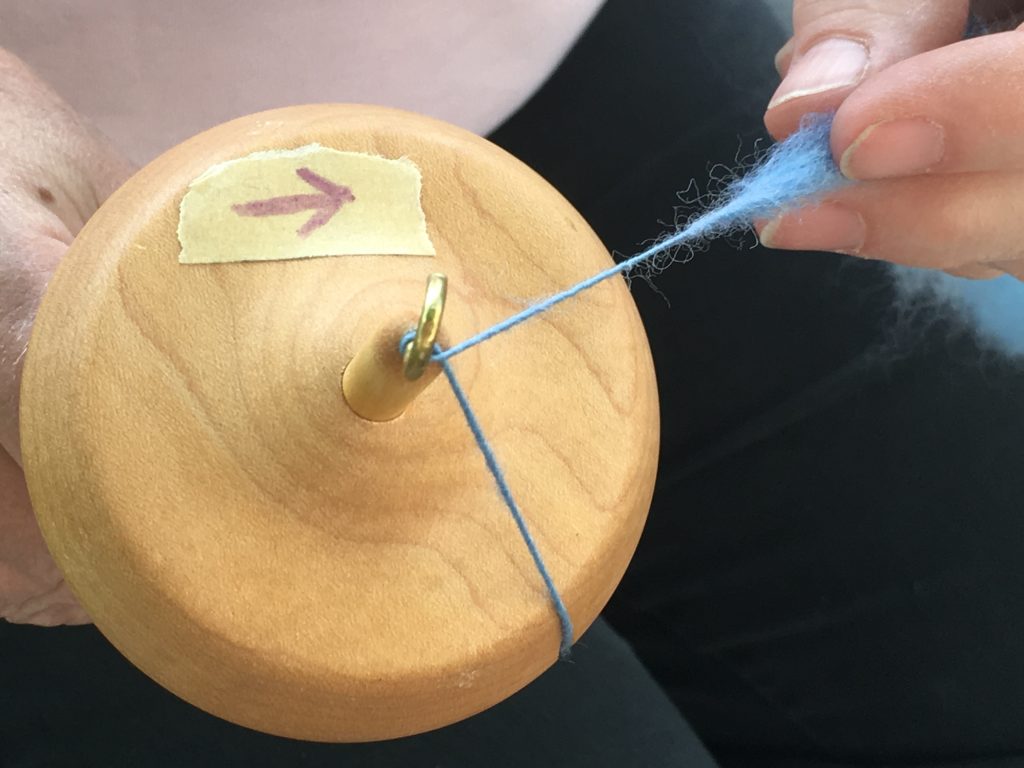

–I get confused as to which way to spin: It is important to always spin the single in the same direction, and spin all the singles that will be plied together in the same direction. (Yes, there are exceptions, but that’s for later.) Try putting a small piece of masking tape on the whorl with an arrow drawn on it that points in the chosen direction, and then use a bigger spindle to ply with, marked to spin in the opposite direction with its own piece of tape.

–My spindle stops spinning the right way and starts to unspin before I want it to: This could mean that you have a lighter spindle than you need for the thickness of single you’re spinning. Your spindle should spin for several seconds before stopping and then unspinning. Try spinning a thinner single to test this. If that fixes the problem, then get a heavier spindle to spin the thicker single you were aiming for.

–When I add new fiber, the single always comes apart at the join: This can happen for three reasons: either the fibers aren’t overlapped a sufficient amount, or they weren’t allowed to ‘mesh’ together enough, or the single is overly thick at the join and the twist jumps over it to thinner sections.

Fibers should overlap at least 1 to 2 inches in a join—more if the fibers are short or slippery, while less may be sufficient for longer, ‘grabbier’ fibers. And, it’s important to really splay out the ends of the joining fibers, so they can grab on and mesh together easier. Finally, allow the joining fibers to taper into the end of the single—if both ends are as thick as the single, then you get a thick spot, which may cause the twist to distribute around the join rather than in it.

–My single breaks while I’m spinning: This can be due to a couple of things: overspinning, which puts too much stress on a thin spot, or spinning with a spindle that’s too heavy for the single you’re making. Look at your single; if there are thick and thin spots throughout, then the breakage will decrease as you become able to spin a consistent single. If you can also switch to a lighter spindle, try that, too; you may find that using a lighter spindle will help prevent overspinning.

A broken single doesn’t mean the end of your yarn, however. Check out this video (fast forward to 10:58 to get right to that section) to see how to re-join a broken single back into your plying.

–My single breaks while I’m plying: Make sure that your singles are able to unwind smoothly from the bobbins or ball on which you wound them. You want some resistance, to keep your singles from tangling, but not so much that there is too much tension on them.

Also, you’re likely using a heavier spindle for your plying. Check your plied yarn: is one single spiraling around the other, while the other is nearly straight? If so, the tension is uneven between the singles, which means the straight single is taking the weight of the spindle. If it’s also thick and thin, then you have to be extra careful. Adjust your grip on the singles so that they feed at even tension into the ply twist, and if you can, shorten the lengths of yarn that you ply before winding it onto the spindle.

–My spindle wobbles a lot as I spin: Practice your method of spinning the spindle without spinning yarn by tying a length of finished yarn onto the hook. Practice making a smooth ‘snap’ without making the spindle swing. While you’re doing this, try an especially smooth spin, and see how the hook and yarn are positioned over the spindle shaft. If your hook gets bent out of place, the yarn won’t center properly along the same line as the shaft, and this can cause a wobble.

Also, as you wind the spun fiber onto the spindle shaft, try positioning the cop in different places on the spindle, trying first to wind the single directly under the whorl. As the cop accumulates more spun fiber, its weight changes how the spindle spins. Try also different shapes of cop—a ball versus a ‘hive’ shape.

What other issues are you having with your drop spindle spinning? Send me an email, and I’ll help you figure it out. And, please visit https://chellecolorado.com/tutorials/ for the rest of my drop spindle videos (and other useful stuff). Also, the Summer 2019 issue of PLY Magazine is devoted to the suspended spindle (yep, drop spindles), so check it out.